ELISA

Elevate your food safety testing with ELISA technology – ensuring reliable mycotoxin and allergen detection with quality and compliance.

Food Safety Testing with ELISA: A Comprehensive Overview

ELISA is a widely used laboratory technique for detecting and quantifying biomolecules with high sensitivity and specificity. In food safety testing, ELISA plays an important role in reliably detecting contaminants such as mycotoxins and allergens, ensuring product safety, maintaining product integrity, and verifying compliance with labeling regulations.

What is ELISA?

ELISA stands for Enzyme-Linked Immunosorbent Assay. It's a widely adopted laboratory method used for detecting and quantifying substances such as proteins, peptides, antibodies, and hormones. The method involves coating a plate with a specific antigen or antibody, followed by a series of reactions that produce a measurable signal, often a color change. This signal accurately indicates the presence or concentration of target substances.

ELISA is highly regarded in food safety laboratories for its ability to deliver precise, rapid, and reliable results, ensuring compliance with stringent food safety standards and helping food producers safeguard public health.

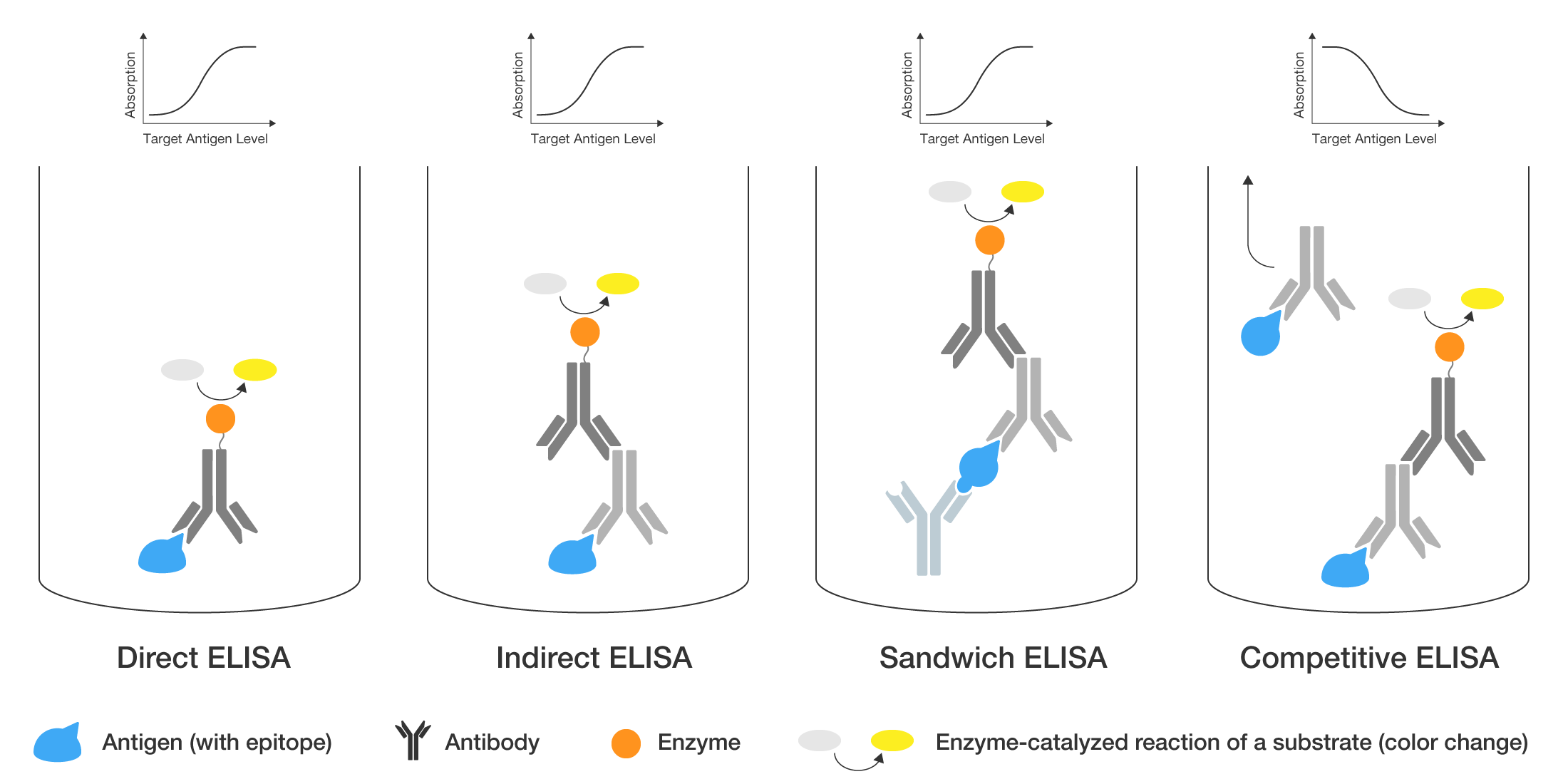

Types of ELISA

There are several types of ELISA assays, each suited to different applications depending on the target substance and required sensitivity.

Direct ELISA

Direct ELISA involves the direct detection of an antigen immobilized on a microplate using an enzyme-linked antibody specific to the antigen. This method is straightforward and quick, reducing the number of steps and potential errors. While it offers rapid results, it may have lower sensitivity compared to other ELISA types. In food safety testing, direct ELISA is useful for the rapid screening of specific foodborne pathogens or allergens in simple samples. Here's the step-by-step process:

- Antigen Coating: The target antigen (such as an allergen or toxin) is directly added to the wells of a microplate. The antigen binds to the surface of the plate through adsorption. This step ensures the antigen is immobilized for detection. Then the wells are washed to remove any unbound antigen or debris. A blocking solution containing a nonreactive protein (such as bovine serum albumin or casein) is added to the wells. This step covers any uncoated surface of the plate, preventing nonspecific binding of antibodies to the plate, which could lead to false-positive results.

- Enzyme-Conjugated Antibody Addition: A specific enzyme-linked antibody is added to the wells. This antibody is designed to bind directly to the immobilized antigen on the plate. Then the plate is washed again to remove any unbound enzyme-conjugated antibodies, preventing non-specific signal generation.

- Signal Measurement: A substrate is added to the wells, which reacts with the enzyme attached to the antibody, producing a measurable signal, typically a color change. The intensity of the signal is directly proportional to the amount of antigen present in the sample.

Indirect ELISA

Indirect ELISA adds a layer of amplification by using a primary antibody specific to the antigen and a labeled secondary antibody that binds to the primary antibody. This increases the assay's sensitivity and flexibility, allowing for the detection of low-abundance targets. It's particularly beneficial for detecting food contaminants and is widely used in food safety labs for monitoring hygiene and detecting pathogens in complex food matrices.

- Antigen Coating: The target antigen (such as an allergen or pathogen) is added to the wells of a microplate and binds to the surface through adsorption. This step immobilizes the antigen for detection. Then the wells are washed to remove any unbound antigen or debris. A blocking solution containing a nonreactive protein (e.g., bovine serum albumin or casein) is added to cover any uncoated areas of the wells. This prevents nonspecific binding of antibodies to the plate, reducing background noise in the assay.

- Primary Antibody Addition: A primary antibody specific to the antigen is added to the wells. This antibody binds to the immobilized antigen. It is not enzyme-linked but forms the first layer in the detection process. The wells are washed to remove any unbound primary antibodies, ensuring only antigen-bound antibodies remain.

- Secondary Antibody Addition: A secondary antibody, which is enzyme-conjugated, is added. This antibody is specific to the primary antibody and binds to it. The secondary antibody amplifies the signal since multiple secondary antibodies can bind to a single primary antibody, increasing the assay’s sensitivity. After binding, the plate is washed again to remove unbound secondary antibodies, ensuring a clean and specific signal.

- Signal Measurement: A substrate is added, reacting with the enzyme linked to the secondary antibody. This reaction produces a measurable signal, such as a color change. The intensity of the signal is directly proportional to the amount of antigen present in the sample.

Sandwich ELISA

Sandwich ELISA employs two antibodies that binds to the antigen at different epitopes, effectively "sandwiching" it. This method offers high specificity and sensitivity, making it ideal for detecting food allergens at low concentrations. Food production companies utilize sandwich ELISA to ensure their products are free from harmful substances, complying with strict food safety regulations. The process in detail:

- Antibody Coating: The process begins by coating the microplate wells with a specific capture antibody. This antibody is designed to bind to a particular antigen (the target molecule) found in the food sample. Then the wells are washed to remove any unbound antigen or debris. A blocking solution containing a nonreactive protein (such as bovine serum albumin or casein) is added. This covers any uncoated surface of the plate, preventing nonspecific binding of antibodies to the plate, which could lead to false-positive results.

- Sample Addition: The sample (such as a food extract) is added to the wells. If the antigen of interest (such as an allergen) is present in the sample, it will bind to the capture antibody immobilized on the plate. Then the plate is washed to remove any unbound substances. This step ensures that only the target antigen remains in the well.

- Detection Antibody Binding: Next, a detection antibody is added. This antibody is also specific to the antigen, but it binds to a different site (epitope) on the antigen than the capture antibody. The detection antibody is typically linked to an enzyme.

- Signal Measurement: After the detection antibody binds, the plate is washed again to remove any excess, unbound antibodies. A substrate solution is then added, which reacts with the enzyme linked to the detection antibody, producing a measurable signal (usually a color change). The intensity of the signal is directly proportional to the amount of target antigen present in the sample.

Competitive ELISA

In Competitive ELISA, sample antigen and a labeled antigen compete for binding to a limited amount of antibody. This format is useful for detecting small molecules and toxins where two antibodies cannot bind simultaneously due to size constraints. It's commonly used for measuring pesticides, mycotoxins, and other small contaminants in food samples. This method is valuable for food safety testing labs focusing on detecting low molecular weight substances that could pose health risks. Here's how the process works:

- Antibody and Sample Reaction: The sample, containing the target antigen, is mixed with specific primary antibodies that are designed to bind to that antigen. As the antibodies react with the free antigen, antigen-antibody complexes are formed. The wells are then washed to remove unwanted components.

- Unbound Antibody Binding: The mixture is then added to a microplate with wells pre-coated with the same antigen. Only unbound primary antibodies (those not bound to the antigen in the sample) can attach to the antigen on the plate, hence 'competition'. After allowing time for binding, the plate is washed to remove any unbound components, ensuring only plate-bound antibodies remain.

- Secondary Antibody Binding: After washing, a secondary antibody linked to an enzyme is added. This secondary antibody binds specifically to the primary antibody that is attached to the antigen on the plate.

- Signal Measurement: Finally, a substrate is introduced, which reacts with the enzyme linked to the secondary antibody, producing a measurable signal (such as a color change). The signal intensity is inversely proportional to the amount of target antigen in the sample. This means the more antigen present in the sample, the fewer free antibodies are available to bind to the plate, resulting in a weaker signal.

Benefits of ELISA

- High Sensitivity and Specificity: ELISAs can detect very low concentrations of antigens or antibodies in complex food samples, thanks to the high specificity of the antibody-antigen interaction. This is crucial for identifying specific foodborne toxins, allergens, or contaminants that are present in very small amounts. The ELISA test most accurately mirrors the chemical reaction that happens in the body when a person has a food allergy reaction.

- Versatility and Flexibility: ELISAs can be adapted to detect a wide variety of targets, including proteins, peptides, antibodies, hormones, and even small molecules, with the appropriate choice of antibodies. This makes it highly versatile for different types of food safety assessments, from detecting allergens to monitoring for specific contaminants.

- Quantitative Analysis: ELISAs provide quantitative data on the concentration of the target analyte in the sample. This is important for assessing the level of contamination of allergens in food products, aiding in risk assessment and ensuring compliance with safety standards.

- Cost-Effective: Compared to many other advanced analytical techniques, an ELISA is relatively cost-effective, especially when testing a large number of samples. This makes it accessible for routine use in food safety testing.

- Ease of Use and Automation: The procedure for ELISAs is straightforward, and many steps can be automated, which reduces the potential for human error and increases throughput. This is beneficial for laboratories that need to process a high volume of samples efficiently.

- Minimal Sample Preparation: ELISAs often require less complex sample preparation compared to other analytical methods. This saves time and reduces the risk of sample degradation or contamination during preparation.

- Robust and Reliable: ELISA kits are designed to be robust and provide reproducible results, which is critical for ensuring consistent food safety testing outcomes across different batches and laboratories.

- Standardization: Many ELISA kits come with standardized reagents and protocols, which help in maintaining consistency in testing procedures and results, facilitating comparative analyses and regulatory compliance.

- Rapid Results: The turnaround time for ELISA tests is relatively short, which allows for timely decision-making in controlling food safety risks and managing potential outbreaks.

- Widely Accepted: ELISAs are well-established and widely accepted methods in the scientific community for detecting specific analytes. Its use in food safety testing is supported by numerous studies and regulatory bodies, adding to its credibility and reliability.

Why is an ELISA Important in Food Production?

ELISAs play a crucial role in food production by providing rapid and accurate detection of allergens and mycotoxins, ensuring the safety and quality of food products. Their high sensitivity and specificity make them an indispensable tool for complying with regulatory standards and preventing food safety incidents.

Identifying Allergens

For products claiming to be allergen-free, our Sandwich ELISAs provide a highly sensitive and specific means to verify these claims, ensuring they meet safety standards and protect consumers with food allergies.

Detecting Toxins

Our Competitive ELISAs (Helica®) allows a very sensitive but reliable detection of dangerous mycotoxins such as aflatoxins or ochratoxins in food products, ensuring that only safe food reaches the consumer.

Regulatory Compliance and Standards in ELISAs for Food Production

ELISA regulatory compliance for food safety testing is essential to ensure that food products adhere to established safety standards, safeguarding consumers from the hazards of contaminants and bolstering consumer trust in your brand. This compliance allows for the meticulous analysis of each ingredient, ensuring the end product is not only enjoyable but also secure for consumption.

Key Regulations and Standards

- FDA Guidelines: In the United States, the Food and Drug Administration (FDA) prescribes guidelines for food safety testing that include the application of ELISAs, particularly for detecting allergens, mycotoxins, and pathogens.

- EU Regulations: The European Union enforces regulations for food safety that encompass the utilization of ELISA for identifying allergens, mycotoxins, and specific protein markers.

- ISO Standards: The International Organization for Standardization (ISO) offers standards such as ISO 22000 for food safety management systems, which recognize the importance of ELISAs in hazard analysis within the food production chain.

Hygiena® is compliant to these standards. For more see our certifications.

Verifying Compliance with ELISA Testing

- Standard Operating Procedures (SOPs): Establish and adhere to SOPs for ELISA testing to guarantee consistent and dependable outcomes.

- Validation and Verification: Consistently validate and verify your ELISA methods to confirm their effectiveness and accuracy.

- Training: Ensure that your team is proficient in ELISA methodologies as well as the pertinent regulations and standards.

- Documentation: Maintain comprehensive documentation of all ELISA tests, including the methods, results, and compliance checks, to ensure accountability and traceability in your food safety practices.

Do you want to learn more about how to implement ELISA in your lab workflow?

Transform your lab's efficiency and accuracy: Contact us to explore our expert insights on integrating ELISA testing, and unlock the full potential of your lab workflow!

Key Takeaways for Food Production Professionals

In conclusion, ELISAs are not merely laboratory techniques; they're a foundational element in contemporary food production, pivotal for verifying the safety and integrity of food items. Their efficiency in identifying specific allergens, pathogens, and contaminants makes the ELISA an essential tool for safeguarding public health and bolstering consumer confidence.

- Highly Sensitive and Specific Detection: ELISAs are renowned for their exceptional sensitivity and specificity in detecting proteins and antigens, establishing them as a cornerstone in food safety testing.

- Versatile Applications in Food Safety: An ELISA's adaptability makes it invaluable across various aspects of the food industry, from screening for allergens and toxins to ensuring the purity and quality of ingredients.

- Improving Production Standards: The integration of ELISAs into food production processes can significantly enhance food safety and quality standards, contributing to more reliable and trustworthy food products.